Why the DJI M350 Drone and H30T Camera Are the Ultimate Solution for Offshore Oil and Gas Flare Stack Inspections

And Why PB Aerial Imaging Is Your Go-To Drone Services Provider

Offshore oil and gas operations are some of the most complex and high-risk industries in the world, and flare stacks—crucial components in managing excess gas during production—present a significant challenge for routine inspections. Traditional methods of flare stack inspections, which often involve scaffolding, rope access, or manned aircraft, are not only risky but also costly and time-consuming. In contrast, drone technology offers a safer, more efficient, and cost-effective solution for inspecting flare stacks, and the DJI M350 drone paired with the H30T camera is leading the way.

In this blog, we’ll explore why the DJI M350 and H30T combo is the ideal solution for offshore oil and gas flare stack inspections and why PB Aerial Imaging should be your trusted provider for these critical services.

1. Unmatched Precision and Reliability: DJI M350 Drone

The DJI M350 RTK is a powerful and versatile drone specifically designed for industrial applications, making it the perfect tool for offshore oil and gas flare stack inspections. Here’s why:

Long Flight Time and Range –

- The M350 offers an impressive flight time of up to 55 minutes and a range of up to 15 kilometers, making it ideal for inspecting remote or hard-to-reach flare stacks, even in offshore environments. Whether you’re operating in calm conditions or facing turbulent winds, the M350 is built to endure challenging weather conditions that are common offshore.

Enhanced Stability and Safety Features

- With a robust airframe and advanced safety features, the M350 can withstand gusty winds and the unpredictable nature of offshore environments. It includes multiple redundancy systems, such as dual GPS, IMUs, and battery backup, ensuring that your inspection continues smoothly even if one system fails.

RTK Precision for Accurate Mapping

- The M350 RTK (Real-Time Kinematic) offers centimeter-level precision, which is critical for creating accurate, high-quality inspection data. For offshore flare stack inspections, where even small changes or wear and tear could lead to major operational risks, having precise data at your fingertips ensures you don’t miss any crucial issues.

2. Cutting-Edge Imaging: H30T Camera

The DJI H30T Camera is another game-changing piece of technology that makes the M350 drone a top choice for offshore flare stack inspections. Here’s why the H30T is the ideal imaging solution:

Multi-Sensor Capabilities

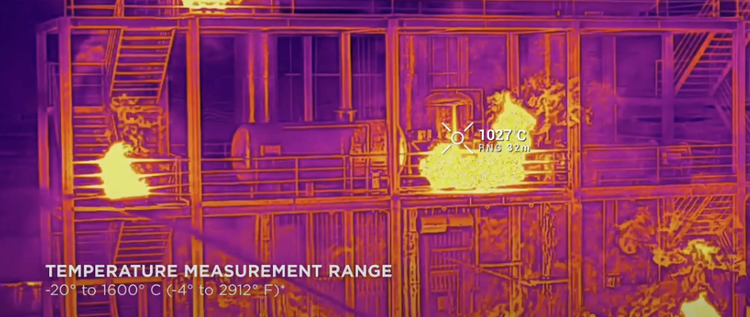

The H30T features a powerful combination of thermal, optical, and laser ranging sensors in one compact package. For flare stack inspections, this multi-sensor capability allows for:

- Thermal Imaging: Spotting heat anomalies or leaks in flare stacks, which can be a sign of equipment failure or inefficiency. With its upgraded 1280x1024px sensor and wider temperate measurement range, Overheating components and defects can be detected before they cause a system failure or serious issue.

- High-Resolution Optical Camera: The 48 MP wide camera along with a 40 MP – 34x optical zoom and 400x digital zoom camera allows you to capture sharp, detailed images of the flare stack at both close and long-range distances, ensuring every part of the stack is inspected thoroughly.Laser Rangefinder: The Lidar feature enables precise distance measurement, which is critical for structural assessments of flare stacks and other offshore infrastructure.

Night and Day Inspection Capabilities

- With the H30T’s thermal and high-resolution optical sensors, inspections can be carried out day or night, providing flexibility for scheduling and ensuring you can monitor flare stacks in real-time, regardless of lighting conditions. This is particularly important offshore, where weather patterns can change unexpectedly.

Real-Time Data for Immediate Decision Making

- The H30T allows for real-time streaming of data back to the operations team. The combination of live-streamed visuals, thermal data, and precise distance readings ensures that potential issues can be detected instantly, allowing for timely decision-making and reducing downtime.

3. The PB Aerial Imaging Advantage: Why Choose Us

While the DJI M350 and H30T are exceptional pieces of technology on their own, the real value comes when you combine them with the expertise of PB Aerial Imaging. As a leading provider of drone services for the offshore oil and gas industry, we bring several advantages to the table:

Industry Expertise

- PB Aerial Imaging specializes in drone inspections for challenging industries like offshore oil and gas. Our team has extensive experience working with complex flare stack systems, understanding the nuances of the offshore environment, and identifying the unique needs of our clients. This expertise translates into safer, more efficient inspections that deliver actionable insights.

Advanced Data Analytics

- We don’t just provide imagery—we offer actionable data. At PB Aerial Imaging, we use the latest data processing and analysis tools to convert your drone footage into high-quality reports that are easy to understand. Our inspections are detailed and thorough, helping you track long-term asset health and identify potential issues before they become problems.

Safety First

- Safety is our top priority. Offshore flare stack inspections are inherently risky, but by using drones, we remove the need for personnel to be in hazardous situations. Our operators are highly trained and follow strict safety protocols, ensuring that every mission is completed with the highest standards of care.

Fast Turnaround Time

- Time is money in the oil and gas industry. Our team at PB Aerial Imaging works efficiently to deliver quick turnarounds on inspections. With drones, you can complete inspections in a fraction of the time it would take using traditional methods, leading to faster decision-making and reducing costly downtime.

Regulatory Compliance

- We understand the regulatory requirements involved in offshore oil and gas inspections. PB Aerial Imaging adheres to all CAA, EASA, and local aviation regulations, ensuring that your drone inspections are compliant with industry standards.

Conclusion: A Safer, More Efficient Future for Offshore Flare Stack Inspections

When it comes to offshore flare stack inspections, the combination of the DJI M350 Drone and H30T Camera is unparalleled in its precision, reliability, and versatility. This advanced technology streamlines the inspection process, reduces safety risks, and provides high-quality data that can be used for predictive maintenance and decision-making.

But having the right tools is only part of the equation. With PB Aerial Imaging as your drone services provider, you gain a partner who understands the offshore industry’s challenges, adheres to the highest safety standards, and provides fast, actionable insights to improve your operational efficiency.

For your next offshore flare stack inspection, choose PB Aerial Imaging and experience the future of industrial inspections—safer, smarter, and more cost-effective.